CIPP Corp. is a nationwide network of Cured-In-Place Pipe (CIPP) lining contractors fully committed to delivering cost-effective, long term pipe rehabilitation solutions for sanitary, storm and potable water piping systems. As part of the Vortex Companies, CIPP Corp. is backed by the nation’s leading manufacturer of line materials, resins and equipment, helping to ensure consistent quality, on-time delivery and fair pricing to its contractors and ultimately the project owners.

What is the CIPP Process?

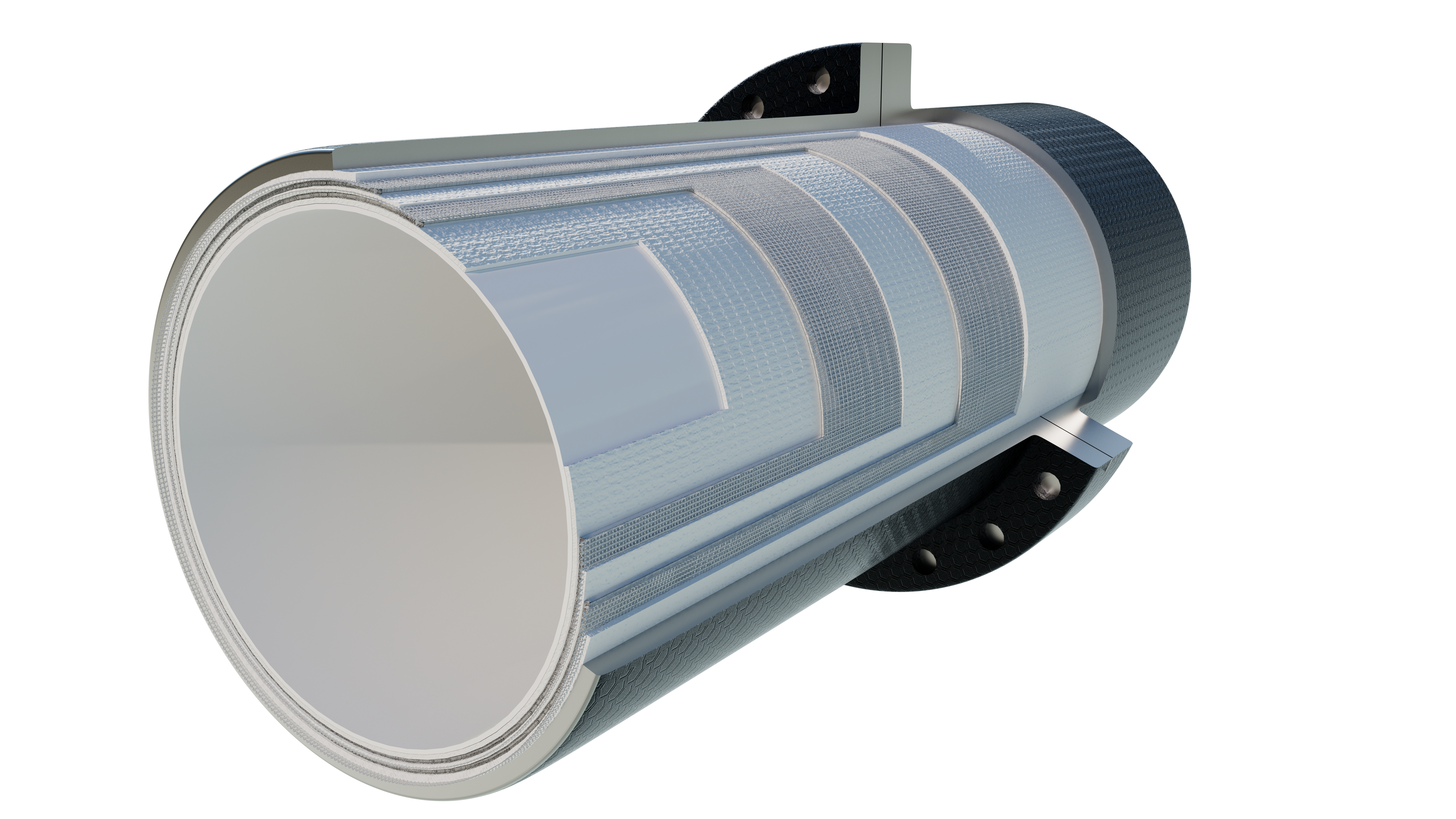

Cured-in-Place Pipe rehabilitation is the process of insetting a resin saturate felt liner into a damaged or leaking pipe. It is then expanded to fit the interior of the host pipe,Hot water, steam or UV light is then used to activate, then cure, the resins until the liner become a pipe-within-a pipe. Laterals are reinstated using a robotic tool. Once the newly lined pipe section is inspected, it is placed back into service after just a few hours. The CIPP Lined pipe is now seamlessly molded to the host pipe, preventing infiltration and exfiltration, restoring the structural integrity of the pipeline, and eliminating weakening joints.

Cured-in-Place Pipe forms a much smoother surface than concrete and clay pipe and actually increases the flow capacity. This piping eliminates joints, effectively preventing root intrusion and environmental corrosion, while stopping leaks. Additionally, Cured-in-Place Pipe is installed using trenchless technology, eliminating costly and time-consuming excavation.

Millions of feet of Cured-In-Place Pipe materials have been installed worldwide and have withstood every corrosive environmental factor and the test of time. CIPP Corp. difference is a commitment to providing the most innovative pipeline rehabilitation technology available with the least amount of environmental disruption. CIPP Corp. offers an affordable, long-term, less disruptive solution to all of your pipeline rehabilitation needs.

Interested in becoming a CIPP Corp. licensed installer, contact

CIPP H20®: Responding to the Need for Cost-Effective Water Main Renewal

In response to growing demand, CIPP Corp. offers the newest innovation in CIPP liners for potable water applications. CIPP H20® was developed in partnership with United Felts, a global leader in CIPP liner design and manufacturing, to deliver an NSF-certified liner system for potable water main rehabilitation.

FEATURES

|

|

| Download Brochure |